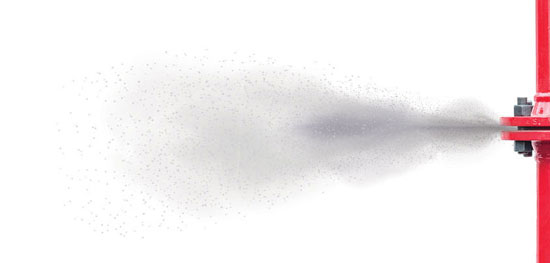

In the event of gasket failure at flange connections, sometimes powerful or even fine swirling sprays can be generated, which can be distributed over a wide area in the system. Spray Control spray protection sleeves are used to prevent the resulting risk of injury to operating personnel.

Decision-maker facts

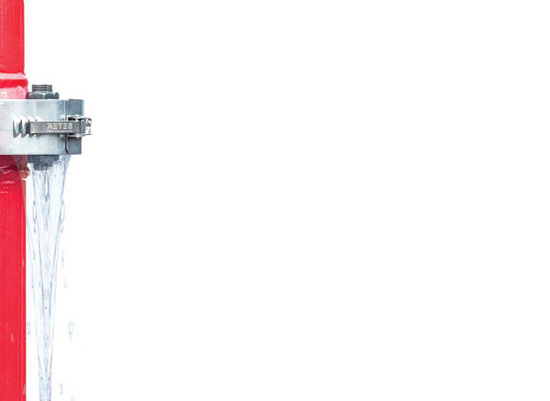

In the event of a leakage, the splash guard has the task of immediately relieving the escaping jet and discharging it without pressure, especially when irritating or corrosive, toxic, hot or flammable media are involved. However, the splash guard must never seal the flange, as otherwise an impermissible, uncontrolled pressure build-up would occur, which would lead to spraying again. The Spray Control spray protection system from Betek has proven itself for this task. Made of stainless steel

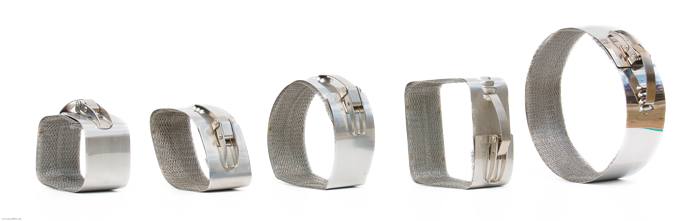

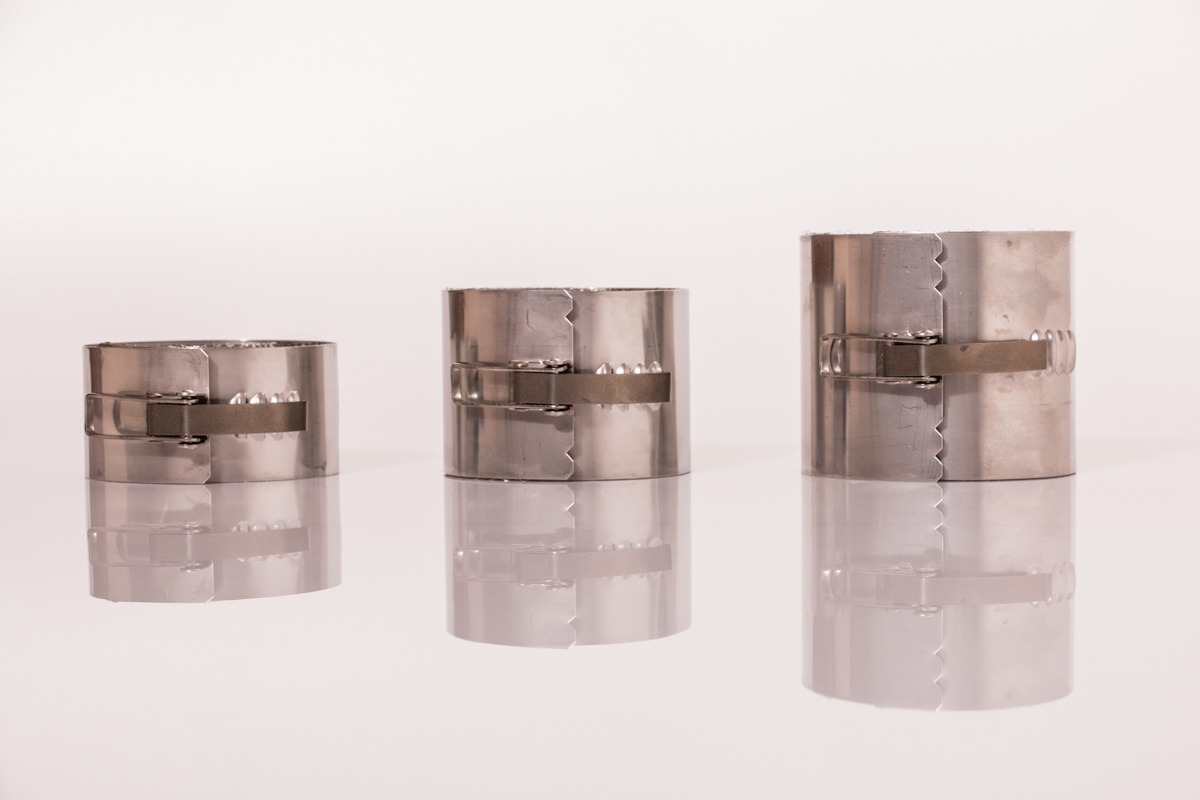

WSt.Nr. 1.4404 (ASTM 316), the sleeve is resistant to oils and chemicals, unlike plastic sleeves it does not become brittle and can be used up to 400°C. An internal net immediately decompresses the escaping spray. The medium drips downwards without lateral deflections, even high pressures (e.g. steam) are immediately dissipated. The integrated mesh prevents the sleeve from slipping and adapts to the gap between the flanges. The sleeve can also be used on flanges without a sealing gap. The splash guard can be fitted quickly and securely thanks to its clip lock. According to the manufacturer, the splash protection system is available for round flanges in all nominal sizes for DIN and ANSI. For other diameters, square and oval flanges, the collar is manufactured according to the customer’s requirements. Standard widths are 50, 70 and 90 mm.

Our article in Chemical Engineering